Room to grow: generating energy from waste in Australia

22 June 2021

The Australian government’s National Waste Policy aims to reduce waste and maximise resource use and efficiency. Its corresponding Policy Action Plan includes (amongst others) targets to recover 80% of all resources from waste streams, and halve the amount of organic waste sent to landfill by 2030. This is a positive step towards maximising resource efficiency; however, we query whether something is missing from this ambitious strategy: acknowledgement of the role of energy from waste (EfW) solutions.

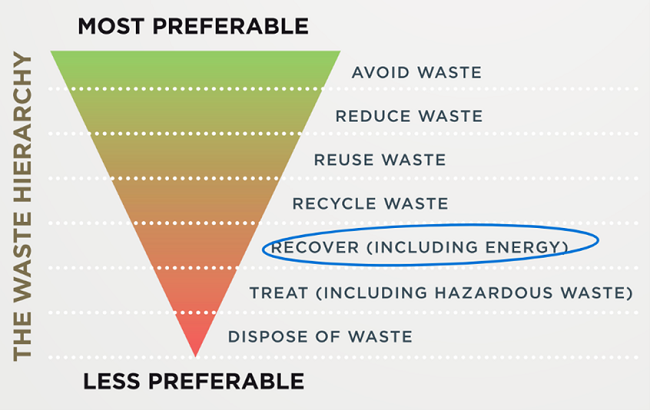

Energy recovery on the waste management hierarchy

Formally embedded in most Australian state and territory policy frameworks, the waste management hierarchy promotes efficient resource use by outlining the preferred order for material management and treatment options. When a product cannot be avoided, re-used or recycled, the hierarchy states that it should be processed for energy recovery. This is where EfW comes in.

EfW in the Waste Management Hierarchy (adapted from Australian Government National Waste Strategy 2018)

Also known as ‘waste to energy’, EfW technologies use residual materials to generate electricity, heat, fuel, and other useful by-products. The technology captures and uses energy from products otherwise destined for landfill – where decomposing materials produce methane for decades, noting greenhouse gas is 25 times as potent as CO2 - adding to Australia’s carbon footprint. Alongside greenhouse gases, landfilled waste also produces leachate which requires treatment.

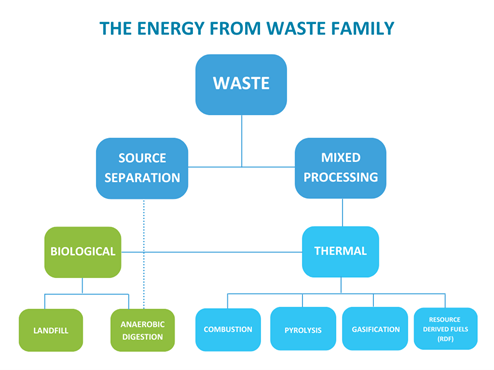

The EfW family includes thermal technologies such as combustion, pyrolysis, and gasification, as well as anaerobic digestion, a non-thermal process that creates biogas.

The May 2021 report by Arup and the Clean Energy Finance Corporation (CEFC) identified a strong potential pipeline of EfW projects between now and 2025, following the financing of Australia’s first two (2) large-scale thermal facilities in Western Australia. The first of these – Avertas Energy in Kwinana, south of Perth – is slated to come online in the next 12 months.

The report estimates that harnessing new investment opportunities in EfW could generate more than 10,000 jobs in infrastructure construction, 1,400 of which would be ongoing operational roles in both metro and regional locations. The report also highlights the emissions reduction potential of this pipeline of investment opportunities – which could avoid more than three (3) million tonnes of CO2 equivalent in methane emissions otherwise produced under a business-as-usual pathway of landfill disposal.

Alongside growing investor interest in thermal combustion projects, awareness of the role of anaerobic digestion is growing, particularly as a part of diverting organic waste from landfill. Controlled anaerobic digestors take residual organic matter and create biogas that can be used for heating, electricity, or fuel, and digestate, which is a nutrient-rich alternative to chemical fertilisers that can contribute to improved soil health. Increasingly, councils are introducing FOGO (food organics garden organics) bins to households, as seen in the recent SA Valuing Food Waste Strategy, NSW mandating of FOGO by 2030, and the federal government’s recently announced 2021 Budget that includes a $67 million commitment to new FOGO initiatives, all of which shine the spotlight on non-thermal EfW solutions.

While EfW is well-established in Europe and abroad, investment in Australian projects has historically been more limited, with the NSW Department of Planning, Industry and Environment describing it as an “emerging technology” in Australia. There are several reasons for this.

The Kwinana project is stated to divert one-quarter of Perth’s post-recycling waste from landfill, at the same time generating enough electricity to power 50,000 homes and preventing the emission of nearly half-a-million tonnes of CO2 equivalent each year. Such figures show the potential for EfW to create jobs, save dwindling landfill space and generate cleaner energy while reducing emissions.

Avertas Energy was Australia’s first large-scale EfW project to reach financial close. (Source: Energising resource recovery: the Australian opportunity, Arup & CEFC)

Why isn’t Australia generating EfW at scale?

Why therefore are other states of Australia taking so long to adopt treatment of residual materials by EfW? In Australia, it would appear that public understanding of how modern EfW projects operate is lacking, with emotive headlines often blurring the line between political rhetoric and science-based evidence. As a result, new developments – particularly those using thermal combustion methods – can be contentious and unpopular with local communities.

Modern combustion EfW facilities have high-tech filtration systems that neutralise odours, allowing them to co-exist alongside communities. Denmark’s Amager Bakke facility in Copenhagen is a case in point; its state-of-the-art pollution controls make it so clean that the ski slope designed atop the project has become a celebrated tourist attraction. Today, such sophisticated technology coupled with strict public health and environmental regulations across all Australian states and territories mean that new energy recovery facilities are clean, safe and sustainable; however, attaining a social licence to operate remains challenging for project developers. Outdated, yet persistent, narratives frame new proposals as dirty incinerators that threaten public health.

Skiing on top of Amager Bakke, Copenhagen (Source: Kallerna, Wikicommons)

Education is key in upending these misleading perceptions and revealing modern thermal EfW facilities as clean, high-tech waste solutions that are integral in remedying Australia’s increasingly costly landfill-dependent habits.

Australia has historically lagged our international peers when it comes to integrated material management, but there is a silver lining when it comes to EfW: we have the opportunity to learn from Europe’s experience. In the early pivotal years, Europe’s EfW journey was marred by planning oversights and in some cases under-regulation. On the contrary, in Australia, policy guidelines for EfW are emerging across all states and territories, with the exception of Tasmania and the Northern Territory (while the ACT has a policy, it has ruled out thermal treatment of waste) and these, along with regulations, can help ensure that waste-to-energy feedstocks consist of residual materials only.

To assist with developing and greater acceptance of EfW, it is imperative first and foremost that there is a systems-based approach to managing materials in Australia, one that is underpinned by the waste management hierarchy as we move towards a genuine circular economy that emphasises design, extended producer responsibility and sustainable natural material management. Facilities must also be designed to take feedstocks comprising genuine residual materials only, with international best practice material recovery adopted (e.g., mandatory source separation). Robust policy and regulatory frameworks across all areas of WARR that work in tandem are equally important; in an integrated system, these frameworks will help states appropriately manage material streams.

In looking to Europe, we must also acknowledge that while the ambitious federal and state resource recovery targets are supported, evidence from numerous EU members (and other countries) that have established decades-long WARR systems (that Australia does not have) show that consistently hitting the 70% target has not been achieved to-date. For example, during the period of 2010 to 2016, landfilling in the28 EU member states decreased from 29% to 25%. Meanwhile, municipal waste recycling rates differ widely between European countries, ranging from 68% in Germany to 0.3 % in Serbia in 2017. That said, smart, longer-term planning that considers the national 2030 80% recovery target is imperative to future-proof EfW facilities while protecting longer-term net-zero and circular economy goals. Such an approach is incumbent on the states and territories adopting comprehensive material management strategies that incorporate the entire hierarchy rather than enforcing arbitrary caps or limits on EfW that will simply deter investors – and thereby further entrench unsustainable landfilling habits!

To date, the state-based policy approaches taken by Queensland and South Australia would appear to be the most workable, given their link to European standards; relying on the EU’s proven regulatory framework is important as it provides Australian project proponents with the necessary reference plants and data that are critical from both a procurement and operational perspective, and plays a key role in obtaining approvals, including a social licence to operate. In particular, South Australia’s 2020 thermal EfW position statement locates EfW solutions within an overarching, integrated strategy of higher resource recovery, safeguarding waste management hierarchy preferences. In other states, more challenging frameworks are under consideration. By enforcing arbitrary thresholds on new facilities that are not informed by European best practice frameworks, these approaches risk locking in less sustainable waste management practices. Unlike the European predicament, in Australia it is this over-regulation of EfW that could threaten our net-zero and circular economy aspirations.

Achieving a balance in Australia

The current siloed and isolated approaches to EfW from individual states and territories benefit neither industry nor communities – and certainly not the environment - as we continue to see 27 million tonnes of materials being landfilled. It is vital that policy makers incorporate energy recovery solutions within their policy solutions to maximise resource recovery – we need to minimise the amount of valuable material going to landfill and maximise recovery, and this cannot be done by simply restricting EfW, it requires a consistent systems-based approach to material and infrastructure in accord with the waste management hierarchy.

Tapping into the potential of the EfW industry requires balancing economic incentives for financing within a forward-looking policy and regulatory approach that future-proofs Australian material management.

Innovative thinking and new approaches are needed to overturn misconceptions, such as EfW facilities being big, polluting beasts. Another common preconception – as noted in the CEFC’s recent report – is that new EfW developments require significant scale and long-term feedstocks of 200,000+ tonnes per annum to generate appropriate return on investment. Yet mounting research and evidence from overseas indicate that this is not the only approach. For example, approaches to EfW can employ industrial symbiosis principles within the growing trend toward ‘eco-industrial parks’, as highlighted by the World Bank. Under such an approach, EfW facilities are integrated within self-sufficient industrial precincts, where residual materials from one facility can be processed to generate power or heat for another.

Australian examples of this precinct approach to EfW are already emerging. In mid-2020, to support economic recovery following COVID-19, the NSW government committed $185 million to the Parkes Special Activation Precinct in the state’s Central West, which will feature recycling facilities, as well as material and energy recovery plants. This pioneering project reveals just one (1) way of pursuing a distributed and more equitable, smaller-scale energy recovery landscape.

To foster innovation and catalyse Australia’s low-carbon, circular economy transformation, an aligned national material management strategy that captures all pathways in an integrated system is needed. Such an approach would encourage streamlined frameworks among the states and territories, including clear guidance for EfW projects. This would encourage investment while ensuring that mainstream material management practices can continue to move up the waste management hierarchy.

The 2030 targets of the federal government’s National Waste Policy Action Plan are just over eight (8) years away and we must maximise the contributions of thermal and non-thermal EfW to come close to meeting these goals. To do so, energy recovery projects must be understood as one (1) tool within an integrated national WARR policy landscape that is coordinated among the states and territories.